Product Details

Industrial Automatic Digital RO Control Panel

The Digital Control panel is different and very easy to use as compared to the analog control panel, touch color screen reverse osmosis system controller is a multi-function controller with a combination of resistance-type touch screen + PLC program control and online conductivity monitor, it is designed for the system control and water quality testing of reverse osmosis system.

Description

Reverse Osmosis Controller

Product Information

The Digital Control panel is different and very easy to use as compared to the analog control panel, it also same controls the working and synchronizes all the equipment in a Particular touch color screen reverse osmosis system controller is a multi-function controller with a combination of resistance-type touch screen + PLC program control and online conductivity monitor, it is designed for the system control and water quality testing of reverse osmosis system.

The instrument is with 7-inch big touch screen, 16:9 display rate, 65536 color resolution ratio, and rich and dynamic display making human-computer information interaction easy.

PLC control and conductivity collection circuit: update American high-speed MCU computer processing system, control the outside IO input and relay output in real-time, the system is well designed and considered the highly stable, highly reliable, anti-interference, full digitization.

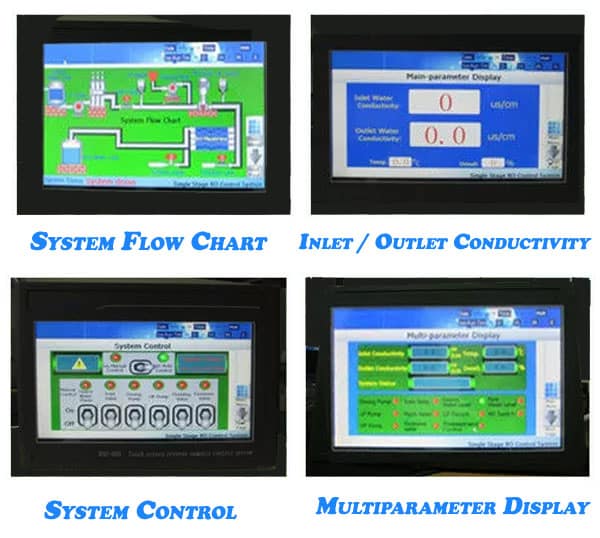

The display content of the interface is mainly: conductivity value monitoring interface, system input signal monitoring, output state display, dynamic system process chart, manual controlling interface, setting interface, etc. following the process state of the system in real-time, which makes people could completely control the whole system easily.

The instrument is available in two versions: single-stage RO control system and double-stage RO control system, the reverse osmosis controller could monitor the conductivity of source water, first-stage production water, second stage water production water at the same time. With isolated 4-20mA output and RS232 communication system (RS232 adopt MODBUS RTU communication agreement), making the communication between instrument and computer, PLC remote communication, and internet.

The single-stage reverse osmosis control system makes the complete system realize automatic control and unattended monitoring. It could be widely used for pure water equipment, seawater desalination, and reverse osmosis systems in many industries.

RS232 interface, standard Mod-bus communication agreement(RTU), which makes it can be easily connected with PLC. PC could send out read instructions, then read inlet conductivity value, outlet conductivity value, and relay control status.

Technical Information

The purpose for use at Single stage reverse osmosis and double-stage reverse osmosis could be selected!

1. Collection point of input signal:

The water level of the raw water tank, for checking with or without water

Low-pressure switch of the first stage (before the first-stage high-pressure pump)

High-pressure switch of the first stage (after the first-stage high-pressure pump)

The low water level of the mid tank

The high water level of the mid tank (if no mid tank, the high water level terminal is free, and the low water level can be replaced by a low-pressure switch)

High-pressure switch of the second stage (after the second-stage high-pressure pump)

The high water level of the second-stage pure water tank (checking of water full)

Communication switch of pretreatment (when pretreatment is working, the system is on standby.

2. Controlling point of output:

A. Raw water pump; B. Inlet valve; C. High-pressure pump of the first stage; D. Flushingvalve; E. Over-limit discharge valve of first stage conductivity; F. High-pressure pump of the second stage; G. Over-limit discharge valve of the second stage; H. Relay of alarm (could be connected audible and visual alarm)

3. Conductivity measurement

Raw water conductivity :0~20μS/cm or 0~2000μS/cm;

The conductivity of first-stage reverse osmosis:0~200μS/cm;

The conductivity of second-stage reverse osmosis:0~20μS/cm

Temperature test: 0-60°C

Conductivity sensor: 1.0cm-1, cable length 5m

4. Other parameters

A. Power supply: external power switch DC24V/1A; B. Load capacity of relay output connection: 5A/250V AC 3A/24V DC;

C. Relay output: normal open single contact; D. Precision:1.5 level; E. Working pressure of conductance: 0~0.5Mpa;

F.Temperature compensation: temperature compensation is calculated based on 25°C

G.Outline dimension: 163mm×226.5mm×80mm(height × width × depth)

H. Size of holes: 215mm×152mm (width × height); I. Installation: panel mount

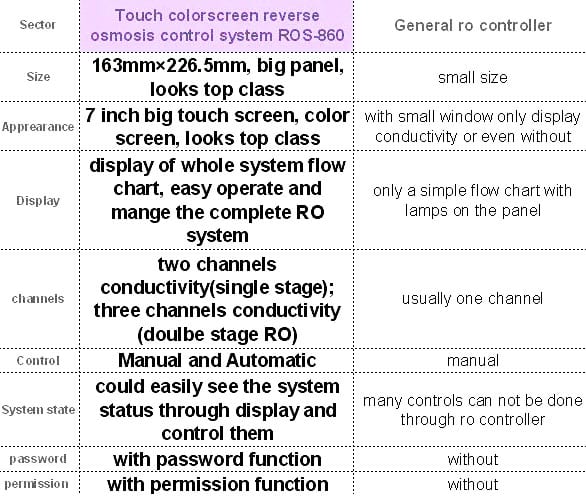

Compare With General RO Control Panel

Some Display Interface

Additional information

| Display: | System flow chart display |

|---|---|

| Password function: | password protection function |

| Control | Automatic control |

| Install | Panel installation |

| Operation | Touch control |

| Channels | Two channels or three channels measure conductivity |

| Power | DC 24V |

| Measure | Conductivity, TDS |

| Application | Use for reverse osmosis system control |

Reviews

There are no reviews yet.